PIR LIGHT sandwich panel

PIR LIGHT sandwich panel

Overview

- Sandwich panels

Description

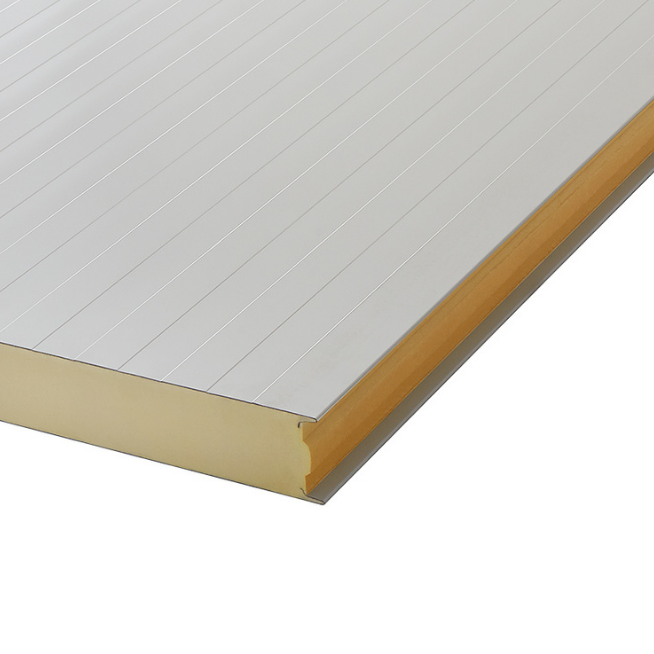

ECONOMICAL WALL SANDWICH PANEL

PIR LIGHT sandwich panel with rigid polyurethane core is coated in steel cladding. It guarantees thermal stability (aging lambda at 0.022 W/mK) with thinner panels. The ” Cold storage joint” (labyrinth joint) used makes the panels maintain the highest tightness and continuity of thermal insulation.

The panel is capillary-inactive and practically non-absorbent. It is a perfect solution for those who need a wall sandwich panel, retaining all its qualities as an external cladding, including a good insulator, but in an economical version.

Its huge advantage is lightness – comparable to boards with a polystyrene core. At the same time, PIR Light provides better thermal conductivity when using a thinner version of the panel (60 instead of 100 mm).

PIR LIGHT sandwich panels are characterized by:

- stability of thermal parameters – with aging lambda at 0.022 W/mK;

- great resistance to soaking and capillary inactivity (no water rising);

- lightness make the panels an excellent alternative to those with a polystyrene core;

- the economical solution while maintaining the most important functions of a PIR sandwich panel;

- highly resistant to mold and fungal infestation, and even nesting by vermin (insects, rodents, or birds).

| Designation | PIR LIGHT sandwich panel | |||

| Core | Rigid polyurethane foam, PIR (nominal apparent density: 37 kg/m3) | |||

| Cladding thickness [mm] | 0.4 | |||

| Steel grade | S250GD | |||

| Coat | SP Polyester 25 μm, SP Polyester 15 μm | |||

| Effective width [mm] | 1150 | |||

| Overall width [mm] | 1170 | |||

| Panel length [mm] | 2500 – 18000 | |||

| Core thickness [mm] | 50 | 60 | 80 | 100 |

| Weight [kg/m2] | 8.3 | 8.7 | 9.5 | 10.2 |

| Insulating efficiency, Uc [W/m2 K] | 0.48 | 0.37 | 0.28 | 0.22 |

| External fire performance | FR* | |||

| Reaction to fire | B-s2,d0 | |||

* Fire-resisting

| Panel length | Panel side | Cladding thickness [mm] | Profiling ** | Coat | ||||||

| Min. [mm] | Max. [mm] | SP Polyester | SP Polyester Mat Pearl | Cesar | PVC (Foodsafe) | Aluzinc | Stainless steel | |||

| 2500 | 18000 | Outer | 0.4 | L | x | |||||

| Inner | 0.4 | L | x | |||||||

**Profiling abbreviations:

L – Lined (different than for PIR Standard and PIR Plus wall panels)